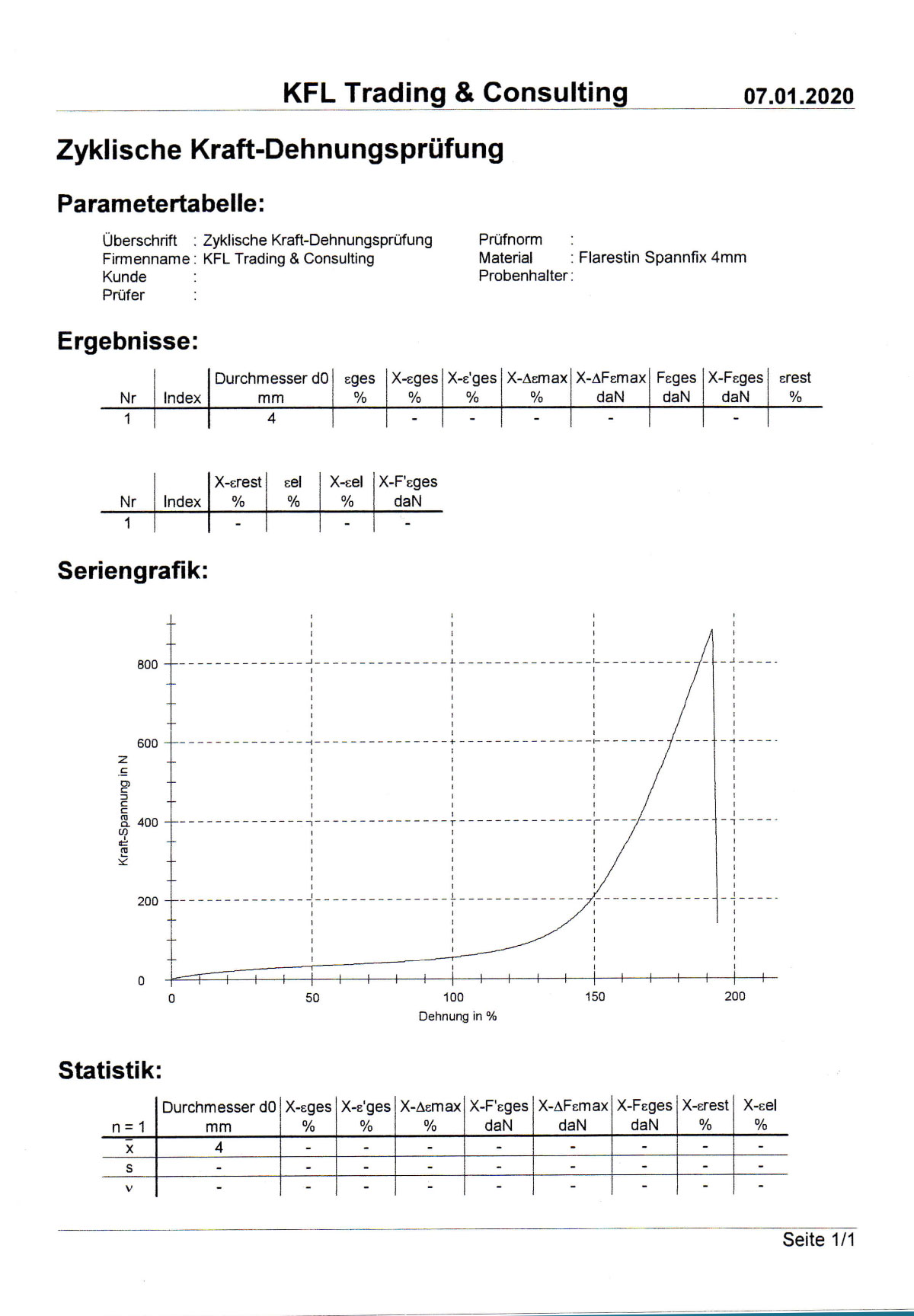

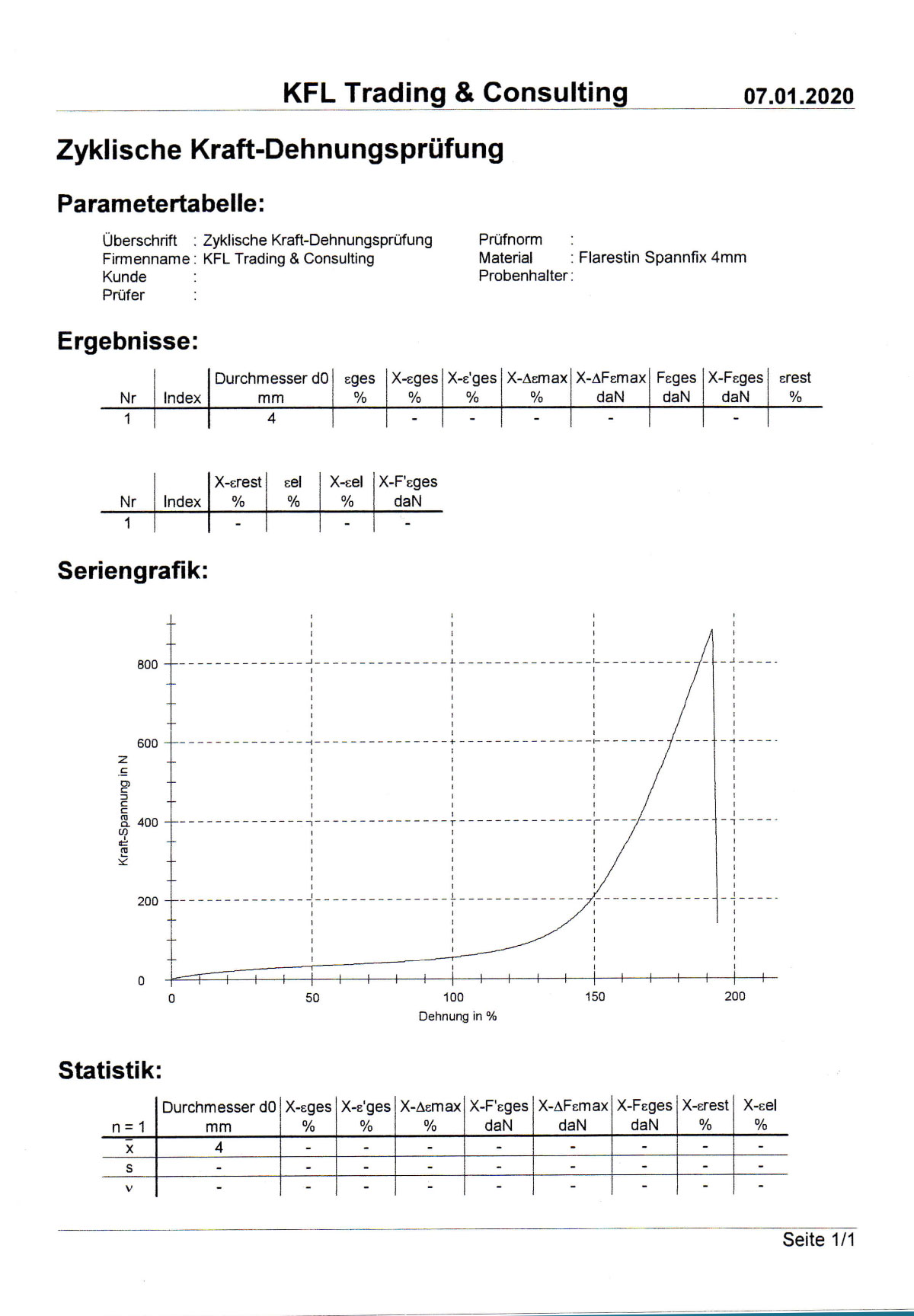

Tested according to practical application, double clamped, hook hooked into loop

The wear or breaking load of our products depends on many parameters. Basically our rubber ropes have an elongation of approx. 100 %. The durability here depends on factors such as pretension and the frequency of elongation. However, factors such as humidity and temperature can also have a considerable impact on the force/elongation behaviour. In addition, the friction on our products has an impact on the durability.

Products made of 6 mm rubber cord generally have less wear and tear due to the higher mass in relation to the above factors. Fatigue of the force/elongation occurs later under the same conditions as with products made of 4 mm rubber cord.

The breaking loads are shown in the attached diagrams. These values serve as average values from our series tests.

A safety factor of 20 % must always be taken into account.

For all products, especially for outdoor use, we recommend a three-month visual inspection of the functional test.

English

English  Deutsch

Deutsch